Window manufacturing software, a specialized tool within the construction industry, empowers businesses to streamline and optimize the design, production, and installation of windows. One such software, “WindowSuite”, provides a comprehensive platform for manufacturers, allowing them to create accurate window designs, generate production orders, and manage customer data efficiently.

The relevance of window manufacturing software stems from the intricate nature of window design and production. These systems enable manufacturers to reduce errors, enhance productivity, and meet customer demands precisely. A significant historical development in this field was the introduction of computer-aided design (CAD) integration, which revolutionized the ability to create complex window designs with ease.

This article delves into the key features, benefits, and industry trends surrounding window manufacturing software. We will explore its role in modern window manufacturing and provide valuable insights for businesses looking to optimize their operations.

Window Manufacturing Software

Window manufacturing software is a crucial tool for businesses in the construction industry, offering a wide range of essential aspects that enhance efficiency, accuracy, and overall productivity.

- Design Automation

- Production Planning

- Inventory Management

- Order Processing

- Customer Relationship Management

- Quality Control

- Data Analysis

- Integration with Other Systems

These aspects are tightly interwoven, forming a comprehensive ecosystem for window manufacturing. Design automation enables the creation of accurate and detailed window designs, while production planning optimizes the manufacturing process to minimize waste and maximize efficiency. Inventory management ensures that the right materials are available at the right time, and order processing streamlines communication with customers. Customer relationship management helps businesses track interactions and provide personalized service, while quality control ensures that windows meet the highest standards. Data analysis provides valuable insights into operations, allowing businesses to identify areas for improvement. Finally, integration with other systems, such as accounting and enterprise resource planning (ERP) software, creates a seamless flow of information across the organization.

Design Automation

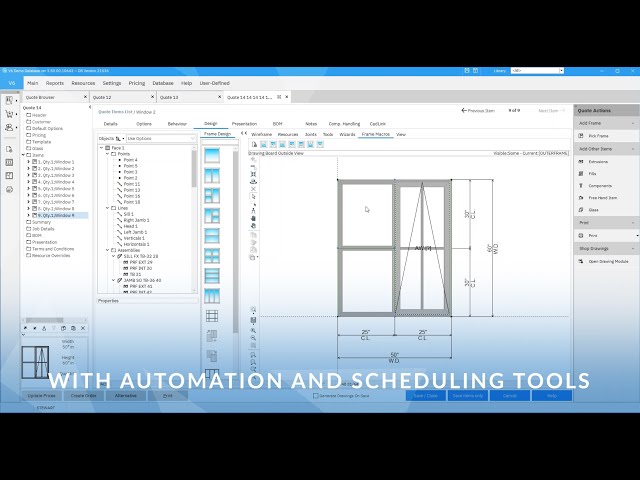

Design automation is a critical component of window manufacturing software, enabling the creation of accurate and detailed window designs with minimal manual effort. This powerful tool automates various design tasks, such as calculating dimensions, generating profiles, and checking for code compliance, significantly reducing the time and resources required for window design.

Window manufacturing software with integrated design automation capabilities empowers manufacturers to quickly explore multiple design options, optimize window performance, and ensure structural integrity. Real-life examples include software that utilizes parametric modeling to generate window designs based on a set of predefined parameters, allowing for rapid customization and adaptation to specific project requirements.

The practical applications of design automation in window manufacturing software extend beyond efficiency gains. By automating repetitive and error-prone tasks, manufacturers can improve design quality, reduce the risk of human error, and streamline the entire manufacturing process. Moreover, design automation facilitates collaboration between designers, engineers, and production teams, fostering a seamless flow of information and reducing the likelihood of costly rework.

In summary, design automation is a transformative technology that revolutionizes window manufacturing by automating complex design tasks, enhancing design accuracy, and streamlining the overall production process. Its integration into window manufacturing software empowers businesses to meet the evolving demands of the construction industry and deliver high-quality windows efficiently and cost-effectively.

Production Planning

Within the realm of window manufacturing software, production planning assumes a central role, orchestrating the seamless flow of materials, resources, and processes to ensure efficient window production. This multifaceted aspect encompasses several key components, each contributing to the overall success of the manufacturing operation.

-

Scheduling

Production planning software organizes and schedules production activities, allocating resources and setting deadlines to optimize production flow and meet customer delivery expectations.

-

Material Management

Effective production planning requires the timely availability of materials. The software manages inventory levels, triggers replenishment orders, and tracks material usage to prevent shortages and minimize waste.

-

Capacity Planning

Production planning software analyzes production capacity and workload to identify potential bottlenecks and optimize resource allocation. This ensures that production capabilities align with customer demand and avoids production delays.

-

Quality Control Integration

To maintain high-quality standards, production planning software can integrate with quality control systems to monitor production processes and identify potential defects. This enables proactive interventions and ensures that windows meet the desired quality specifications.

By integrating these multifaceted aspects, window manufacturing software empowers businesses to streamline production planning, reduce lead times, minimize production costs, and enhance overall operational efficiency. The seamless coordination of production activities fostered by these software solutions enables manufacturers to respond promptly to changing market demands and deliver high-quality windows to their customers.

Inventory Management

Inventory management plays a pivotal role within window manufacturing software, serving as the backbone of efficient and cost-effective production processes. This critical component ensures the seamless flow of materials, components, and finished goods throughout the manufacturing cycle, directly impacting production timelines, cost optimization, and customer satisfaction.

Real-life examples of inventory management within window manufacturing software include real-time inventory tracking, automated reordering systems, and integration with material suppliers. These features provide manufacturers with up-to-date visibility into their inventory levels, enabling them to make informed decisions regarding production planning, , and inventory replenishment. By optimizing inventory levels, businesses can minimize waste, reduce lead times, and maintain optimal production capacity.

The practical applications of inventory management in window manufacturing software extend beyond cost savings and efficiency gains. Effective inventory management fosters greater agility and responsiveness to changing market demands. By having the right materials and components available at the right time, manufacturers can adapt quickly to fluctuations in customer orders, seasonal variations, or supply chain disruptions. Moreover, robust inventory management systems provide valuable insights into inventory patterns, consumption rates, and supplier performance, empowering businesses to make strategic decisions and optimize their supply chain.

In summary, inventory management is a cornerstone of window manufacturing software, enabling businesses to streamline production processes, reduce costs, and enhance customer satisfaction. Its integration into software solutions provides manufacturers with real-time visibility, automated reordering capabilities, and data-driven insights, empowering them to make informed decisions and navigate the complexities of the manufacturing industry.

Order Processing

Order processing, a crucial aspect of window manufacturing software, encompasses the efficient management of customer orders throughout their lifecycle. This comprehensive process involves a multitude of interconnected tasks, each contributing to the seamless execution and fulfillment of orders.

-

Order Entry

The initial stage of order processing involves capturing customer orders accurately and efficiently. This includes recording order details, such as product specifications, quantities, and delivery information, to ensure accurate order fulfillment.

-

Order Management

Once an order is entered, it enters the order management stage, where it is tracked and monitored throughout its lifecycle. This involves managing order status updates, coordinating production schedules, and handling any changes or modifications to the order.

-

Scheduling and Production

The order processing system interacts with production planning and scheduling modules to ensure that orders are scheduled and produced efficiently. This includes allocating resources, optimizing production flow, and monitoring progress to meet delivery deadlines.

-

Shipping and Delivery

The final stage of order processing involves coordinating the shipment and delivery of finished products to customers. This includes managing logistics, tracking shipments, and providing real-time updates to customers.

By integrating these facets into a cohesive workflow, window manufacturing software streamlines order processing, reduces errors, and enhances overall efficiency. This enables manufacturers to fulfill customer orders accurately and on time, leading to improved customer satisfaction and increased profitability.

Customer Relationship Management

Within the realm of window manufacturing software, customer relationship management (CRM) plays a vital role in fostering enduring customer relationships and driving business growth. CRM encompasses a diverse array of strategies and technologies designed to manage interactions with customers effectively, streamline sales processes, and enhance overall customer satisfaction.

-

Lead Management

CRM software helps manage and track leads throughout the sales cycle, from initial contact to conversion. It provides a centralized platform to capture lead information, nurture relationships, and qualify leads for sales follow-up.

-

Sales Management

CRM systems streamline sales processes by managing customer accounts, tracking sales activities, and providing insights into sales performance. This enables sales teams to identify opportunities, close deals efficiently, and build stronger relationships with customers.

-

Customer Service

CRM software empowers businesses to provide exceptional customer service by tracking customer interactions, resolving inquiries promptly, and personalizing communication. This fosters customer loyalty and builds long-lasting relationships.

-

Marketing Automation

CRM systems integrate with marketing automation tools to deliver targeted marketing campaigns, track campaign performance, and nurture leads through personalized messaging.

By leveraging CRM capabilities within window manufacturing software, businesses can gain a comprehensive view of customer interactions, streamline sales and marketing processes, and build stronger relationships with their customers. This leads to increased customer satisfaction, improved sales performance, and enhanced profitability.

Quality Control

Quality control stands as a cornerstone of window manufacturing software, playing a pivotal role in ensuring the production of high-quality windows that meet customer expectations and industry standards. The symbiotic relationship between quality control and window manufacturing software manifests itself in several ways.

Firstly, quality control is a critical component of window manufacturing software, providing manufacturers with the tools and capabilities to monitor and maintain the quality of their products throughout the manufacturing process. These software systems incorporate automated inspection systems, statistical process control techniques, and data analysis tools to identify and address potential quality issues proactively.

Real-life examples of quality control within window manufacturing software include real-time monitoring of production processes, automated defect detection, and non-destructive testing capabilities. By leveraging these features, manufacturers can ensure that windows meet the desired specifications, reducing the likelihood of defects and costly rework.

The practical applications of this understanding extend beyond mere quality assurance. By integrating quality control into window manufacturing software, businesses can improve product quality, reduce production costs, and enhance customer satisfaction. Moreover, robust quality control systems provide valuable insights into the manufacturing process, enabling manufacturers to identify areas for improvement and optimize their operations.

Data Analysis

Within the realm of window manufacturing software, data analysis assumes a pivotal role, empowering businesses with valuable insights to optimize operations and make informed decisions. By leveraging data collected throughout the manufacturing process, manufacturers can gain a deeper understanding of their production processes, identify areas for improvement, and enhance overall efficiency.

-

Production Performance

Data analysis provides insights into production performance, enabling manufacturers to track key metrics such as production volume, machine utilization, and cycle times. This information helps identify bottlenecks, optimize production schedules, and improve overall productivity.

-

Quality Control

Data analysis plays a crucial role in quality control, allowing manufacturers to monitor product quality and identify potential defects. By analyzing data from quality control inspections and customer feedback, manufacturers can pinpoint recurring issues and implement corrective measures to enhance product quality.

-

Inventory Management

Data analysis supports effective inventory management by providing insights into inventory levels, usage patterns, and supplier performance. This information helps manufacturers optimize inventory levels, reduce waste, and improve supply chain efficiency.

-

Customer Insights

Data analysis provides valuable insights into customer preferences, buying patterns, and feedback. This information enables manufacturers to tailor their products and services to meet customer needs, leading to increased customer satisfaction and loyalty.

In summary, data analysis is an indispensable aspect of window manufacturing software, providing manufacturers with the knowledge and insights to drive operational excellence. By harnessing the power of data, manufacturers can make informed decisions, improve production processes, enhance product quality, and ultimately achieve greater profitability and customer satisfaction.

Integration with Other Systems

In the realm of window manufacturing, software systems play a vital role in streamlining operations and enhancing productivity. One crucial aspect of these software solutions is their ability to integrate seamlessly with other business systems, creating a connected ecosystem that optimizes data flow and facilitates efficient decision-making.

-

ERP Integration

Integration with enterprise resource planning (ERP) systems enables window manufacturers to connect their production processes with other core business functions, such as finance, inventory management, and customer relationship management. This integration provides a comprehensive view of the business and allows for real-time data exchange, eliminating the need for manual data entry and reducing the risk of errors.

-

CAD/CAM Integration

Integration with computer-aided design (CAD) and computer-aided manufacturing (CAM) software enables manufacturers to streamline the design and production processes. CAD software allows for precise window design, while CAM software generates CNC code for automated manufacturing processes. Integration between these systems reduces the risk of errors and improves production efficiency.

-

CRM Integration

Integration with customer relationship management (CRM) systems provides window manufacturers with a centralized platform to manage customer interactions, track orders, and provide support. This integration enhances customer satisfaction by enabling manufacturers to respond promptly to inquiries and provide personalized service.

-

Supply Chain Management Integration

Integration with supply chain management systems enables window manufacturers to optimize their supply chain processes. This integration provides real-time visibility into inventory levels, supplier performance, and logistics, allowing manufacturers to make informed decisions regarding and inventory management, leading to reduced costs and improved production planning.

In summary, the integration of window manufacturing software with other business systems is a powerful tool for optimizing operations, improving efficiency, and enhancing decision-making. By connecting with ERP, CAD/CAM, CRM, and supply chain management systems, window manufacturers can streamline their processes, reduce errors, and gain a comprehensive view of their business, ultimately leading to increased profitability and customer satisfaction.

Frequently Asked Questions about Window Manufacturing Software

This FAQ section addresses common queries and clarifies essential aspects of window manufacturing software, providing valuable insights for businesses considering its implementation.

Question 1: What are the key benefits of using window manufacturing software?

Window manufacturing software offers numerous benefits, including streamlined design and production processes, reduced errors and rework, optimized inventory management, enhanced customer service, and improved overall efficiency.

Question 2: How does window manufacturing software improve production efficiency?

By automating repetitive tasks, optimizing production scheduling, and providing real-time visibility into the manufacturing process, window manufacturing software significantly enhances production efficiency.

Question 3: Can window manufacturing software integrate with other business systems?

Yes, window manufacturing software can seamlessly integrate with ERP, CAD/CAM, CRM, and supply chain management systems, creating a connected ecosystem that optimizes data flow and facilitates efficient decision-making.

Question 4: What types of businesses can benefit from window manufacturing software?

Window manufacturing software is suitable for businesses of all sizes involved in the design, production, or installation of windows, including manufacturers, fabricators, and contractors.

Question 5: How does window manufacturing software enhance customer satisfaction?

By enabling manufacturers to respond promptly to inquiries, provide accurate order updates, and offer personalized service, window manufacturing software contributes to increased customer satisfaction.

Question 6: What are the latest trends in window manufacturing software?

Recent trends include the integration of advanced technologies such as artificial intelligence (AI) and machine learning (ML) to optimize production processes, improve quality control, and enhance customer experiences.

These FAQs provide a comprehensive overview of the key aspects and benefits of window manufacturing software. By understanding the capabilities and applications of this software, businesses can make informed decisions and leverage its potential to optimize their operations and achieve greater success.

In the next section, we will delve deeper into the specific features and functionalities of window manufacturing software, exploring how these capabilities can be customized to meet the unique needs of different businesses.

Tips for Maximizing the Benefits of Window Manufacturing Software

This section provides practical tips to help businesses leverage the full potential of window manufacturing software and achieve optimal results.

Tip 1: Define Clear Goals and Objectives

Before implementing window manufacturing software, establish clear goals and objectives to ensure the software aligns with your specific business needs.

Tip 2: Choose Software with Comprehensive Features

Select software that offers a comprehensive suite of features, including design automation, production planning, inventory management, and customer relationship management.

Tip 3: Ensure Proper Training and Support

Provide comprehensive training to ensure users are proficient in utilizing the software’s features. Access to ongoing support is crucial for smooth implementation and troubleshooting.

Tip 4: Integrate with Other Business Systems

Maximize efficiency by integrating window manufacturing software with other business systems, such as ERP, CRM, and supply chain management systems.

Tip 5: Monitor and Analyze Data

Regularly monitor and analyze data generated by the software to identify areas for improvement and optimize production processes.

Tip 6: Seek Expert Advice

Consult with industry experts or software vendors to gain insights and best practices for implementing and using window manufacturing software effectively.

Tip 7: Leverage Customization Options

Explore customization options to tailor the software to your specific business processes and requirements.

Tip 8: Stay Updated with Software Enhancements

Regularly check for software updates and new features to ensure you are utilizing the latest advancements and optimizing your operations.

By following these tips, businesses can maximize the benefits of window manufacturing software, streamline operations, enhance production efficiency, and gain a competitive edge.

These tips lay the foundation for understanding how to optimize the use of window manufacturing software. In the next section, we will explore the key considerations for selecting the right software solution for your business.

Conclusion

This comprehensive exploration of window manufacturing software has illuminated its multifaceted capabilities and profound impact on the industry. Key points highlighted throughout the article include the following:

- Optimization of the design and production processes: Window manufacturing software streamlines design and production, reducing errors and improving efficiency.

- Enhanced customer service and satisfaction: By providing real-time updates and personalized service, window manufacturing software contributes to increased customer satisfaction.

- Integration with other business systems: seamless integration with ERP, CRM, and supply chain management systems creates a connected ecosystem, optimizing data flow and decision-making.

The adoption of window manufacturing software is not merely a technological upgrade but a strategic investment that empowers businesses to stay competitive, reduce costs, and deliver high-quality products. As the industry continues to evolve, window manufacturing software will undoubtedly play an increasingly vital role, shaping the future of window manufacturing.